2025. 07. 03.

The responsibilities of the employees in the Technical Planning for Logistic Equipment department are probably only fully understood by true insiders – yet their diverse range of tasks offers fascinating insights even for outsiders. Based in Győr, the team works closely with various interfaces such as vehicle production, suppliers, quality assurance, logistics process planners, and operational logistics. It serves as Audi’s central competence center for the planning of containers used in body and press shops.

After speaking with Department Head Tamás Gacs, Technical Coordinator Endre Adi, and equipment planners Bálint Csőre and Balázs Szabó, we are convinced: without them, no car would ever roll off the production line.

What exactly is your area of expertise?

Our team was established at the start of vehicle production, building on our experience in the engine plant. In the beginning, our main task was to ensure high-quality protection for manufactured and incoming parts – in other words: suitable packaging. This included both universal and custom packaging solutions. Later, we also took over packaging planning for small series in toolmaking. With the integration of all logistics areas into a unified Supply Chain Organization in 2019, central competence centers were created. Since then, the team in Győr has been responsible across Audi for container planning in the body and press shops at all locations. In return, other sites take responsibility for other functional areas in line with our supply chain principle: “One for all.” This approach enables us to use our resources efficiently and avoid redundant development.

Through our active involvement in numerous production ramp-ups, we’ve become familiar with the specific requirements of each location and have evolved into an indispensable part of the material supply process. Our special expertise lies in our ability to understand individual needs while also considering holistic optimization strategies – and this is what makes our work truly unique.

What are you particularly proud of?

We’re proud of our team’s extensive technical knowledge and international experience. And above all, we’re proud that our expertise is now proudly recognized as “From Győr to the world.” We’ve supported, among others, the ramp-up of the plant in Mexico, the production launch of the long-wheelbase Audi A7 in Shanghai, and the project start-up for the Audi FAW NEV Company in Changchun.

Do you have a favorite project?

Not exactly a favorite – but our successful collaboration with Porsche on the PPE project definitely stands out. It was our first major challenge as a competence center and an especially exciting one, as it involved cross-brand collaboration. The launch of the Cupra model in Győr was also particularly significant, featuring many logistics highlights such as new automation solutions. Despite the complexity, it was one of the smoothest-running projects of the past few years.

What is specific to Audi-Hungaria in the process, i.e., unique?

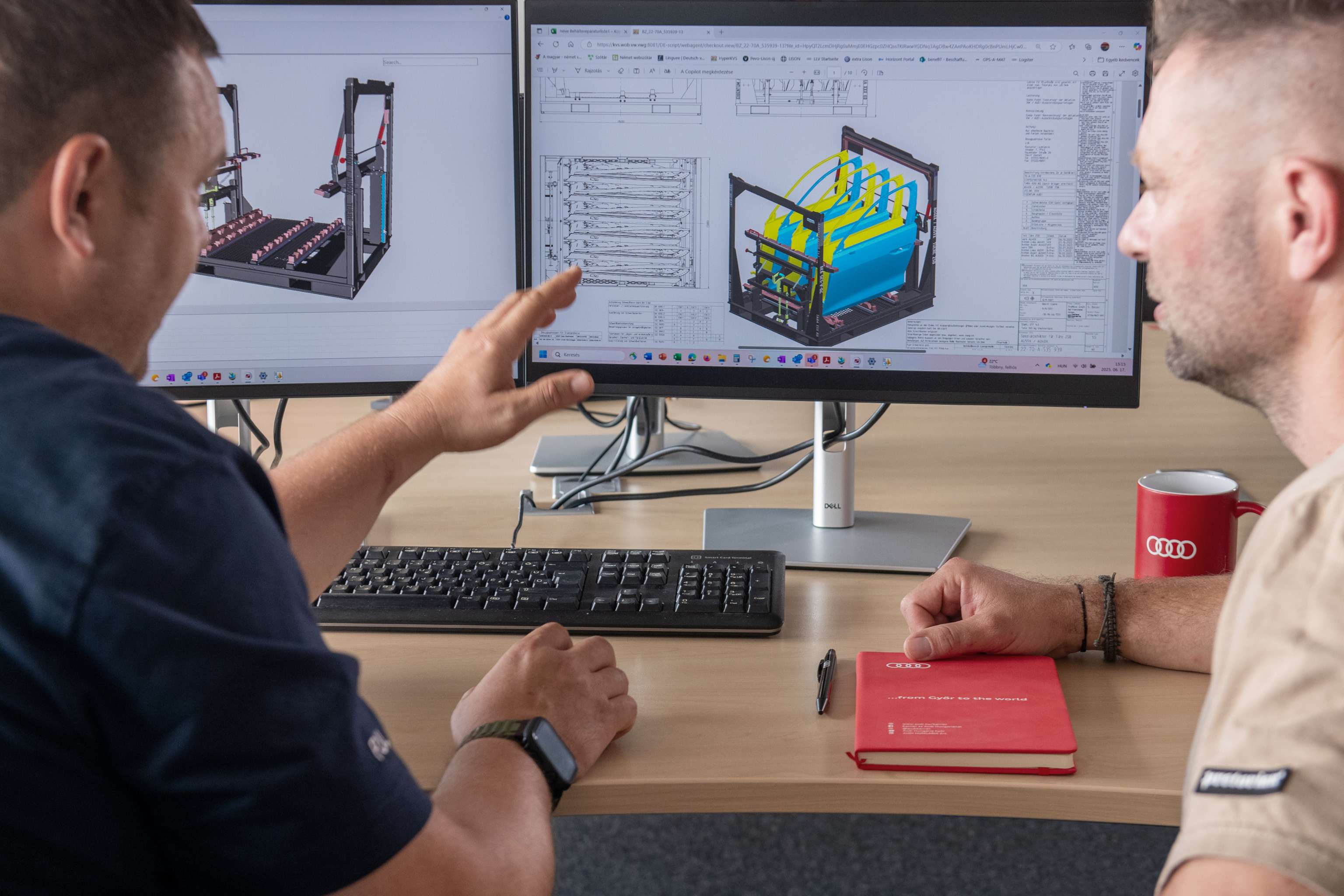

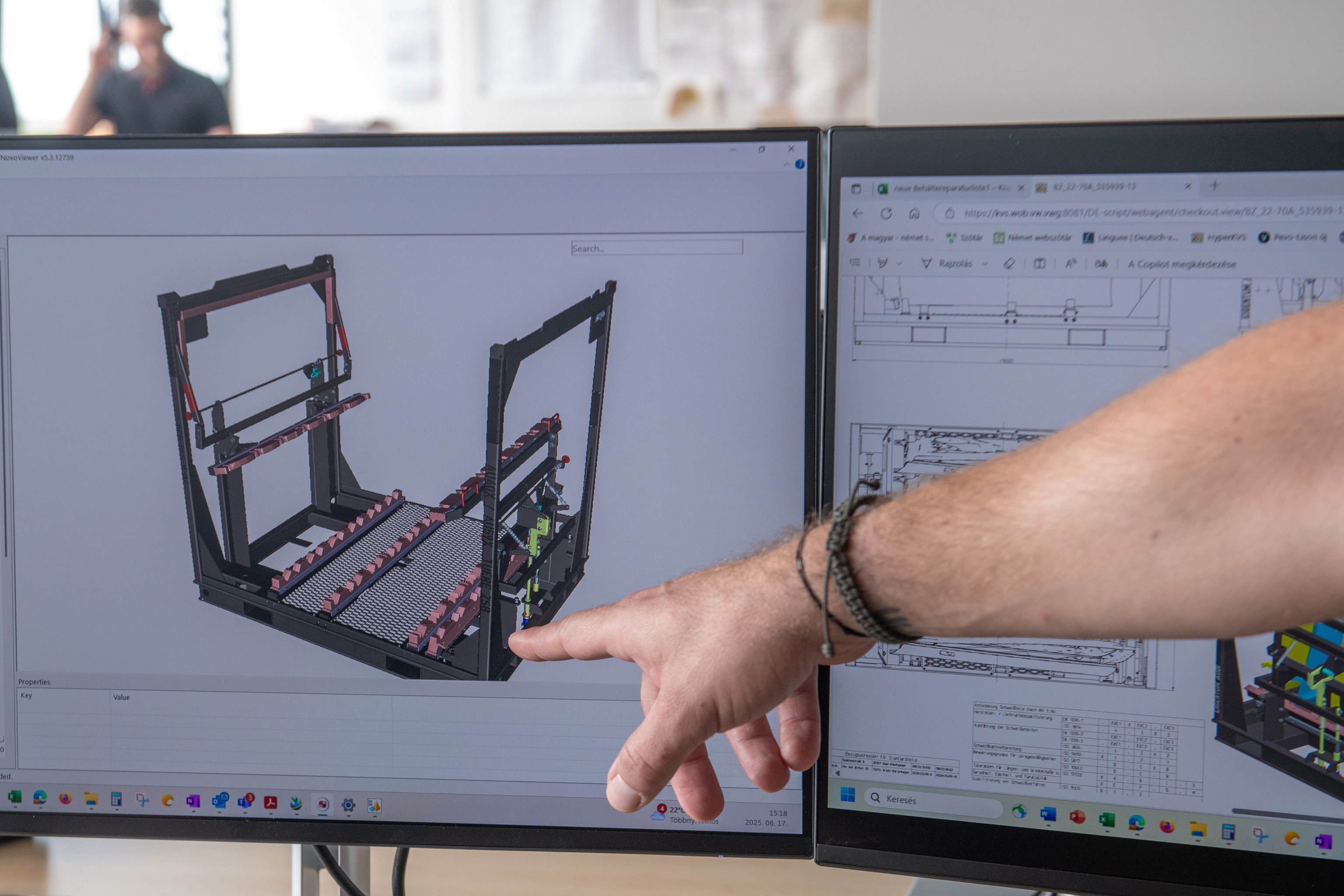

The development of special containers for the body shop is exclusively located with us at Audi. Since this year, we’ve also taken over the technical approval of these special containers – a task previously outsourced.

This not only results in cost savings, but also expands our planning capabilities, making the role of a technical planner even more diverse and appealing. At the same time, it allows us to manage our workload more effectively.

Are there any technological or digital innovations you would like to highlight?

One example is the Supar system, which uses Virtual Reality for the technical approval of special containers. By introducing video-based approvals, we’ve significantly reduced travel costs. However, beyond technological advancements, sustainability is a key focus for us. We're increasingly pursuing a retooling approach – repurposing containers from discontinued models for use with new vehicle models, or extending their lifecycle by assigning them to new areas of application.

But it certainly doesn't work without travel...

Absolutely – our work wouldn’t be possible without international travel. In addition to regular trips to Ingolstadt and Neckarsulm, our colleagues have also been deployed in Brussels, China, and Mexico. The intercultural differences and the wide range of requirements and conditions on-site make every project unique. And that’s precisely the appeal of our work: It requires – and fosters – an immense knowledge base to develop the right logistics equipment for an increasing variety of vehicle types and material flow processes, all while accounting for different levels of automation and technology use.

There are few fields where you need such a comprehensive understanding of every step of vehicle production, combined with a multitude of interfaces – both within and beyond Audi.

Address

9027 Győr, Audi Hungária út 1.

Phone

+ 36 96 66 8888

E-mail

You can read our current news on the News page.

If you need further information concerning our press materials, please, contact our colleagues at the Corporate Communication Department.