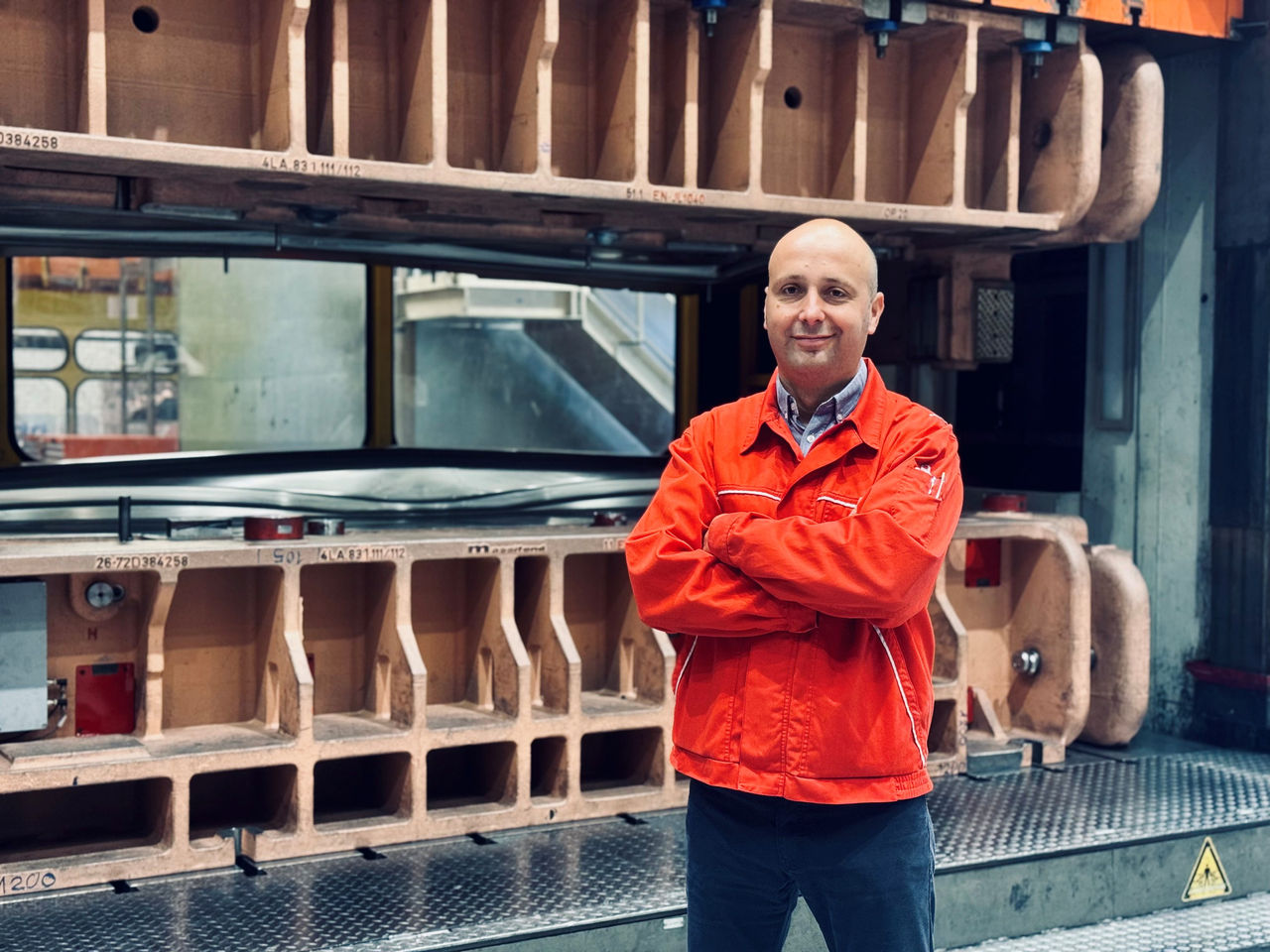

The year was 2004, when Péter Zsolnai, who had been working as a production support engineer at the Audi factory in Győr since 1999, was given a big task. As a member of the team assigned to the Tool Shop under construction and consisting of about 20 people, he went on a nine-month secondment to Neckarsulm, Germany, to start small-scale production of 11 parts for the Audi RS4 model in Győr, based on the professional experience gained in the field.

The experiences in Germany were followed by busy weekdays at home, where the team had to set up the hall building, which was still in the process of being completed. Alongside the fixed-layout production lines envisioned by the design team, workers in yellow safety helmets came and went, filling the space. Based on their previous experience and the best practices, they dreamt up the optimal layout around the machines arriving on the trucks, brainstorming, often gathering around the cable drums for an impromptu meeting.

How much has the Tool Shop changed since then? The three- to four-fold increase in hall size is matched by the increase in production volume. During peak periods, it is not uncommon to see as many as 60 parts for 10 to 11 different projects being produced, and the machinery is constantly evolving, with tasks previously carried out at largely manual workstations now automated. Peter's career path has evolved in parallel with the development of his workplace, and he now works in an indirect position, but closely linked to production. In his new role, he focuses mainly on organisation, in addition to his operational tasks.

"For me, the biggest milestone was the launch of the R8 project in 2006– that’s when my daughter was born. I had to perform at my best at work, while at home I had the best challenge of my life waiting for me. My little girl has since then become a big girl of 18, and the then distant future has become our present. I believe that the future of the Tool Shop is challenging, but we make products that turn heads wherever they appear in the world. Quality will always be in demand. I'm very proud to have been a member of the Audi team for 26 years and the Tool Shop for 21 years."

In January 2007, Tamás Zoltán Molnár came to Győr from Mór, where he had previously worked with press tools, on the recommendation of a friend. He started as a tool design engineer, then moved to surface preparation and is currently Team Coordinator of the Method Design Team that became part of the Tool Shop’s operations in 2010.

"The training process was gradual and well structured, while we initially produced what seemed to be simple body elements, for which we adapted existing method designs, these were gradually replaced from the initial concept phases by the creation of our own method designs, thus building up our professional competence. In the component development phase, several development areas are working simultaneously, as while the car is still being developed and we are already designing and manufacturing the tooling. In today's fast-paced automotive industry, new models are introduced almost every year, and this can only be matched by simultaneous and continuous development in the world of tools."

As the range of activities gradually expanded, so did the range of parts themselves, with the Győr unit being entrusted with the production of a variety of material qualities, aesthetically challenging and motivating requirements, and complex external parts.

"We made our first sidewall tool in 2015, which I'm very proud of. In our company, the side wall is the queen of parts. The tooling for these parts used to be made mainly in Ingolstadt, but today, in our exclusive series production, the entire production cycle is carried out in our company, including the side elements, which are made here in Győr using our own tooling. I think that's the biggest thing we've been able to create in the Tool Shop."

The bodywork components we make with our press tools are backed by the high level of expertise and experience that the Tool Shop team has built up over the last two decades. In the past, our staff used to visit the Group's sites to gather knowledge, but now the exchange of experience goes both ways.

"It's a great feeling to walk down our corridor in the hall, where the projects from previous years mark the key milestones. The list is long and rich. It's uplifting to look back every day at the many memories, the many stories, the many well-bonded teams."

Before becoming an Audi employee in 2014, József Rémai worked as a representative of a supplier in the vehicle factory. An open position at the Tool Shop came up – which he had no prior in-depth information about. It seemed a closed world he wanted to explore, as well as to try out what it was like to work for Audi. Of course, he was attracted by the exclusive series production. At the time, they were supplying parts for the RS models. So he started working as a purchased parts responsible engineer at the Tool Shop.

"I wish all new colleagues the welcome I received from my colleagues. It was a very positive experience to be treated almost like family and this 'good to have you here' environment has been a feature of our team ever since. Of course, the Tool Shop community has outgrown its relatively small size, but the agility, the willingness to work together and the core values have remained, and new colleagues quickly pick up this mentality as well."

Over the past 11 years, József has worked as an exclusive series bodywork product support engineer and then as a tooling product project manager, but every stage of his career has been and still is marked by four or five colleagues who are very close to him. He is currently a project manager in the exclusive series production. We may say that he is the link between the customers and the company, the conduit through which information flows. He participates in committees where the components produced in Győr are presented, and coordinates projects from launch to series production.

"I still remember my first project, the Lamborghini Aventador, where I worked as a purchased parts responsible, and it was definitely challenging to achieve the expected stable quality from suppliers for components made using basically prototype tools and technologies. It wasn't an easy task, but I got a lot of help from my colleagues, from our partner areas, and that helpful attitude has continued ever since. And the product speaks for itself.

I see our task in the current turbulent situation is to create the same quality and flexibility with our daily agile work and our competences that have earned us the trust of our customers. Over the past 20 years, we have proven that we can be relied upon to deliver the highest quality. This is reflected in the new projects we bring in and the expanding customer base, which includes long-lasting relationships with brands such as Audi Ingolstadt, Neckarsulm, Audi Sport, Lamborghini and now Bentley. For 20 years, the Tool Shop has been about continuous growth and development, and I believe we can remain competitive in the long term, thus securing the future of our jobs."

In 2013, Viktória Sebestyén started working as an internal auditor in the central quality management area, where she audited the tool shop on several occasions. Then in 2016, a colleague from the Tool Shop persuaded her to switch to this field and that’s how she made the move. With this change, her internal auditing responsibilities were complemented by process improvement, where she really found her calling. She can fulfil her potential in everyday challenges and professional functions. Here, everyone is open to improving processes.

"The change was not easy, it was an in-depth learning process, because although I knew the exclusive series, the development and production of production tools covers a wide spectrum of activities. It took me a long time to gain the level of insight I now have into the processes. It's also an advantage of my job. Every day I learn and experience something new, I find myself facing a new question. The excitement of novelty, change, new approaches can be overwhelming at first, but it's a phenomenal feeling when you get to the end of a solved question."

What is special about the Tool Shop? Constant change and evolution. New projects, new suppliers, new partners, an organisational restructuring to meet the challenges of the present, or the emergence of competitors – all these factors make it necessary to review, fine-tune, rethink and change processes.

"In this ever-changing environment, the familiar atmosphere is a true anchor. Even though there are a lot of us, almost everyone knows everyone, it's easy to feel at home, which is important for me to feel comfortable at work. Now, on the occasion of the 20th anniversary, we look back on the development of the past years, as success after success gave rise to new activities and functions. The story of the Tool Shop is like a patchwork quilt, created from many different patterns and shapes, made with great love and care, and loved and cherished by all.

I'm proud to be part of the team, proud of the time I've spent here, the continuous development, the teamwork and I’m proud of the respect we have for each other. I would like to continue to strengthen this team in the future. I believe that with our versatility, our diverse activities, our complexity, our adaptability, our solution orientation, we will be an important factor in the future of the Group, because the Tool Shop still holds many opportunities."